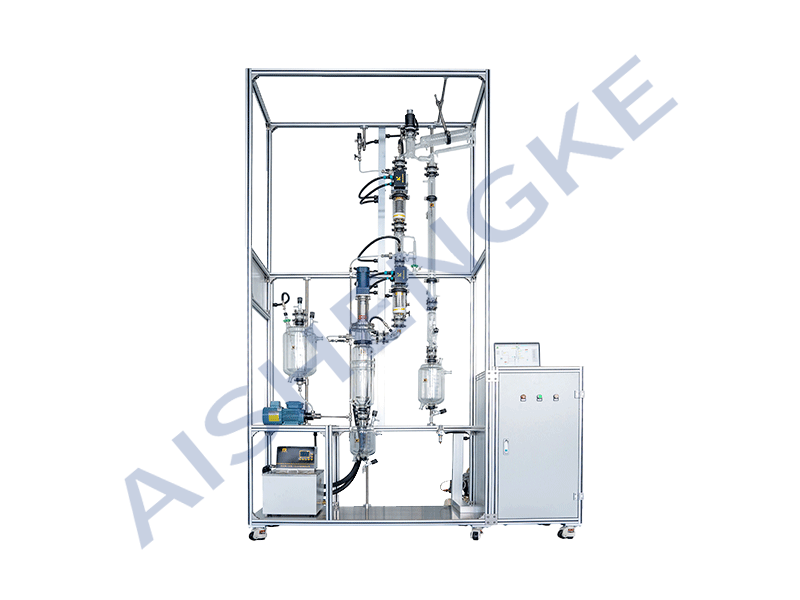

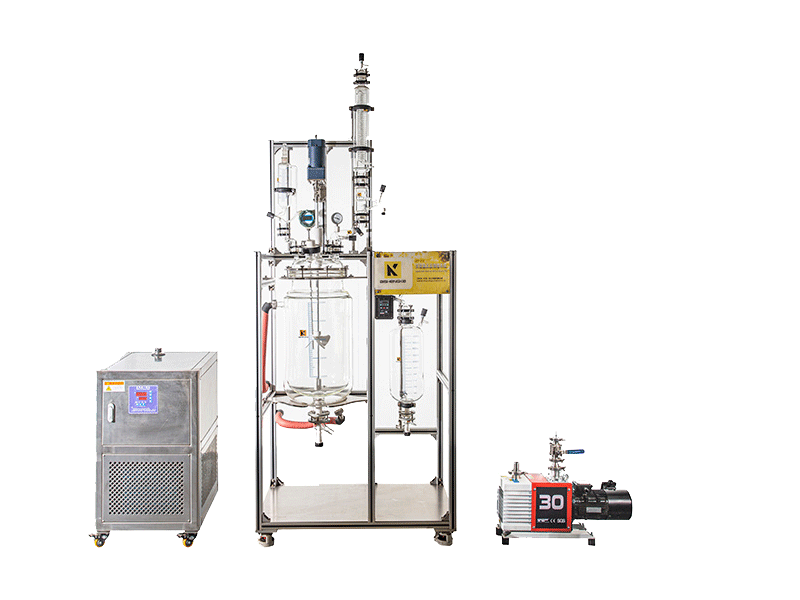

Borosilicate Glass Molecular Short Path Distillation System

Stainless Steel High Pressure Vessels

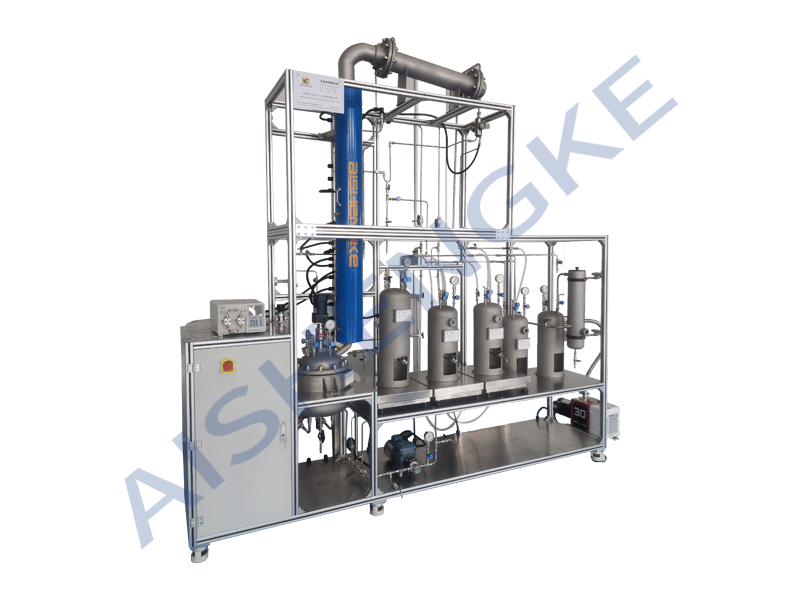

Vacuum Hybrid Fractional Distillation Apparatus

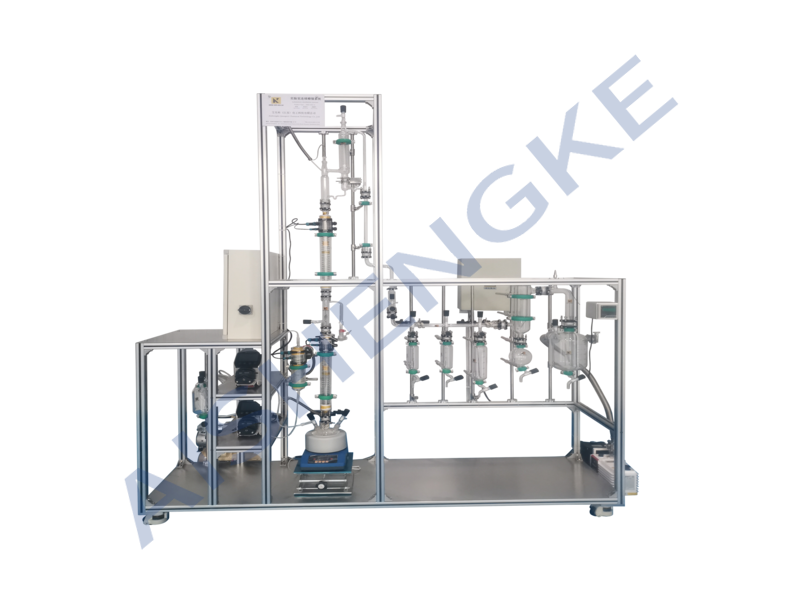

Laboratory Continuous Fractional Distillation Equipment

Atmospheric And Vacuum Extractive Distillation Unit

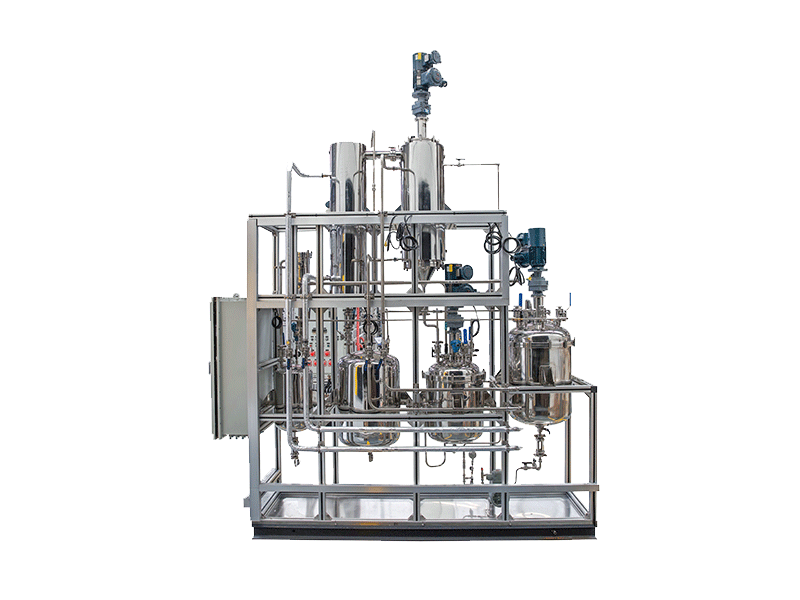

Stainless Steel Pressurized Fractional Distillation Unit

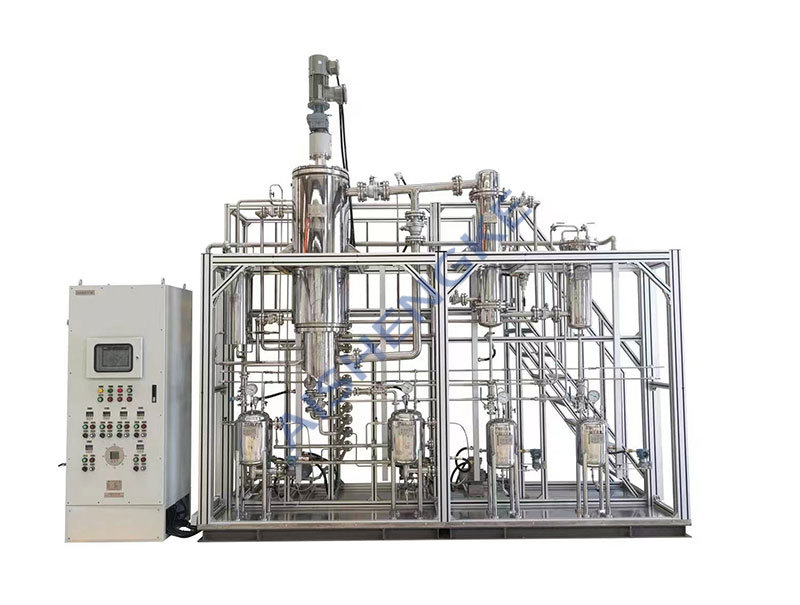

Fractional Distillation Equipment

Molecular Distillation Equipment

Batch Continuous Thin Film Evaporation And Short Path Distillation Equipment

Lifting Double Jacketed 10L Glass Reactor

MO/CVD/ALD semi-conduct precursor material storage and delivery system

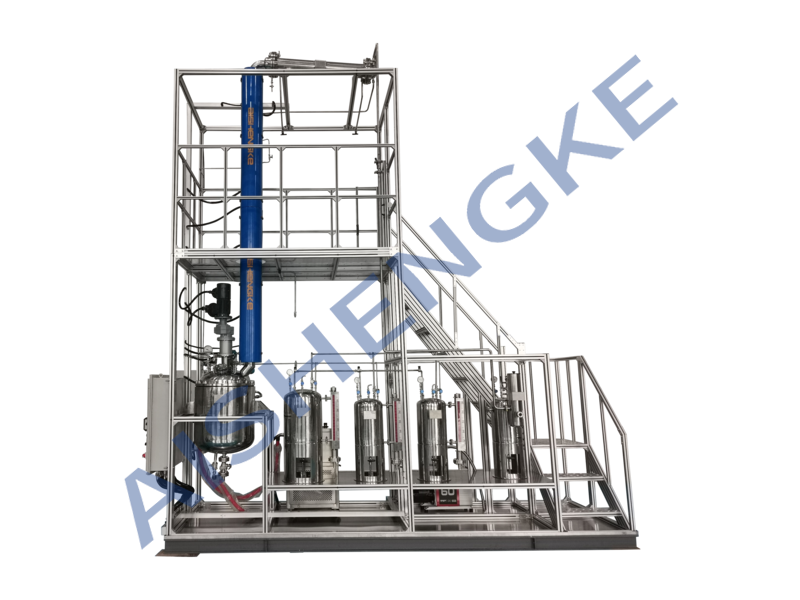

Idustrial Continuous Fractional Distillation Equipment

Upgraded Chemical Pilot 50L Jacketed Glass Reactor

Liftable 10l Stainless Steel Jacketed Reactor

Desktop Laboratory 5l Jacketed Glass Reactor & 5l Glass Reactor

Upgrade 20L Jacketed Pilot Glass Reactor For Laboratory

Upgrade 30L Jacketed Borosilicate Glass Reactor With Distillation Function

Upgrade 10l Double Jacketed Glass Reactor For Laboratory

Upgrade 100l Jacketed Pilot Lab Glass Reactor

1L 2L 3L 5L Laboratory Small Double Jacketed Glass Stirred Reactor

Wiped-Film Distillation Equipment

Laboratory Small Glass Scraped Film Evaporator

Wiped Film Molecular Distillation Equipment

Stainless Steel Laboratory Continuous Wiped Film Evaporation Equipment

Global recruitment of distributors

If you recognize the brand, technology, products and market prospects of Aishengke, we look forward to establishing a strategic partnership with you for win-win cooperation and development. Looking forward to your joining!