Product Category

Multi-tank series reaction unit & Continuous tank reactor

Tank reactors are generally composed of shells, jackets, agitators, inlet and outlet nozzles, sealing devices, reducers, and motors. They are widely used in small tests and industrial production. Chemical reactors are generally classified according to operating conditions. For normal pressure and pressurized conditions, the general small test uses glass reactors for normal pressure conditions, and stainless steel is used for pressurization, and the structure is designed with upper and lower heads.

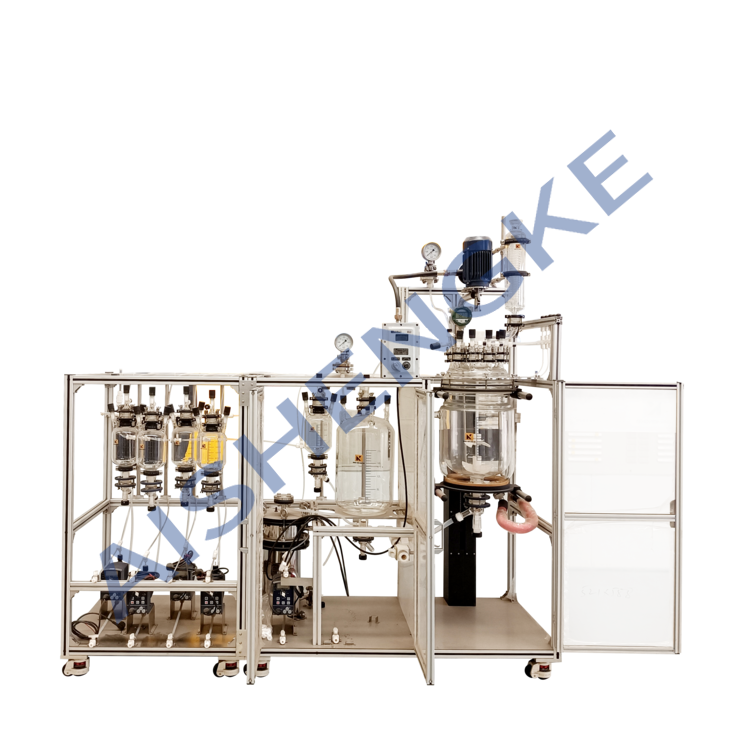

Glass Continuous Purification Reactor

The device is mainly used to remove trace moisture, metal impurities and particles in the product. For some special processes, it is necessary to add deacidification equipment to the system. The entire purification device consists of raw material tank, adsorption column, mixing kettle, filter, precision filter It is composed of a device, an inlet and outlet pump, a product tank, a waste liquid tank and related instruments.

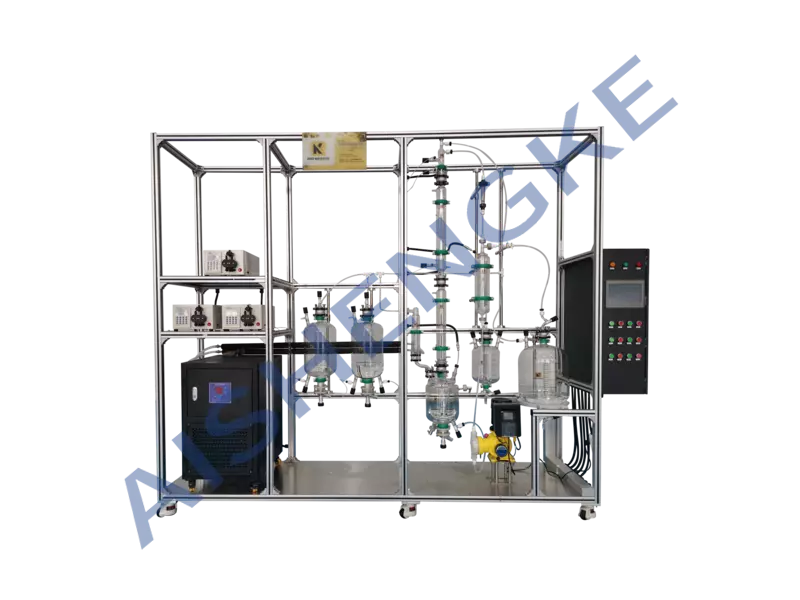

Fixed bed catalytic reaction and hydrogenation unit

The device can be used for hydrogenation, dehydrogenation, oxidation, reforming, cracking and other reactions under normal pressure or under pressure. The device adopts fixed bed, trickle bed and other types of reactors, generally adopts open electric heating furnace, and can also adopt circulating heat transfer oil or steam heating method according to process requirements.

Global recruitment of distributors

If you recognize the brand, technology, products and market prospects of Aishengke, we look forward to establishing a strategic partnership with you for win-win cooperation and development. Looking forward to your joining!

Contact Us

Manager Han: +86 198 5022 2118

Landline: +86 0519-85611172

Fax: +86 0519-85611132

Address: No. 109 Liuyanghe Road, Xinbei District, Changzhou City

language

English

العربية

বাংলাদেশ

Български

Hrvatski

Česky

Dansk

Nederland

Esperanto

Slovenski

filipino

Suomi

Français

Maori

Georgian

Deutsch

Ελλάδα

ישראל

इंडिया

Magyarország

Ísland

Indonesia

Irlanda

Italia

日本語

Sovensko

Հայաստան

한국

Kyrgyz

ປະເທດລາວ

Latvian

Lithuanian

Luxembourgish

Macedonian

Малайская

Maltese

Монгол улс

ဗမာ

नेपाल

Norge

ایران

Polska

Portugal

România

Российская

Србија

Србија

Bosanski

Slovenian

Беларус

España

Sverige

Точик

ประเทศไทย

Türk

Azərbaycan

Uzbek

Việt Nam