Borosilicate Glass Molecular Short Path Distillation System

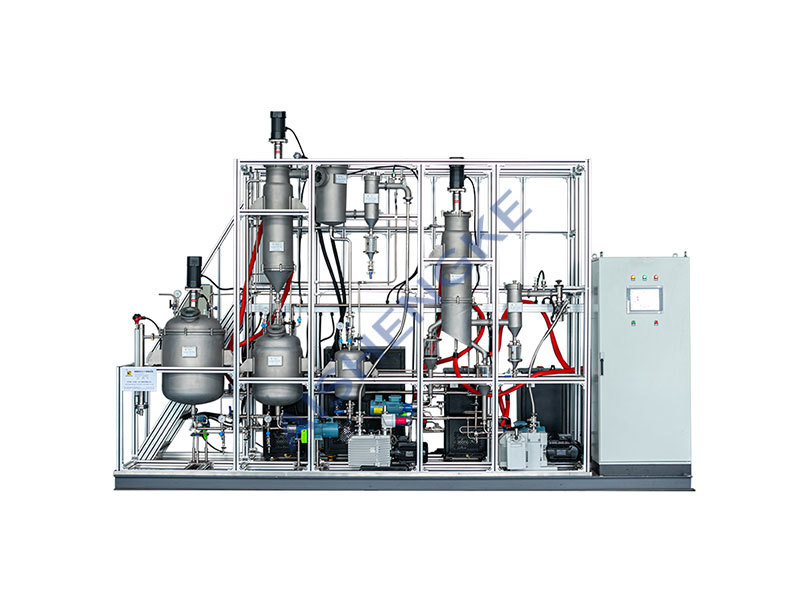

Molecular Distillation Equipment

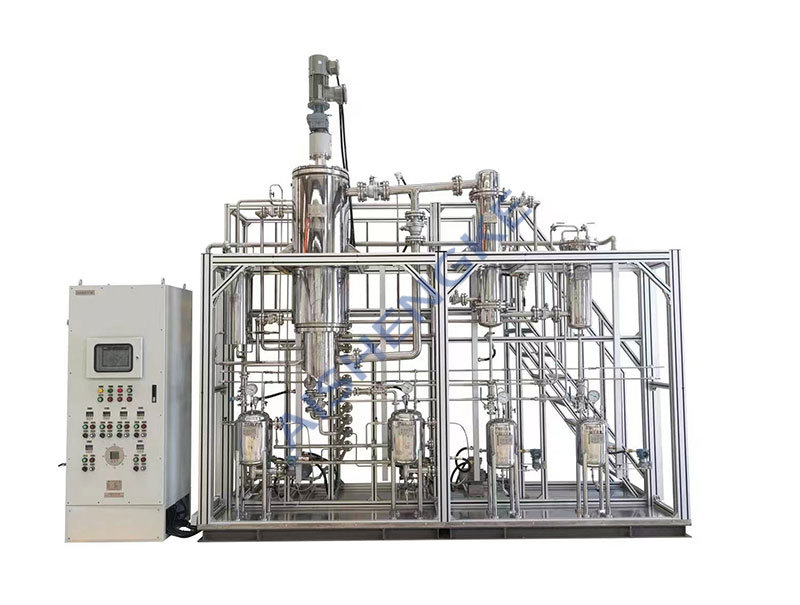

Batch Continuous Thin Film Evaporation And Short Path Distillation Equipment

Wiped Film Molecular Distillation Equipment

Stainless Steel 304 316L Vacuum Wiped Film Molecular Distillation System

Lab scale pilot-scale Industrial scale short-path distillation units

Global recruitment of distributors

If you recognize the brand, technology, products and market prospects of Aishengke, we look forward to establishing a strategic partnership with you for win-win cooperation and development. Looking forward to your joining!