Product Category

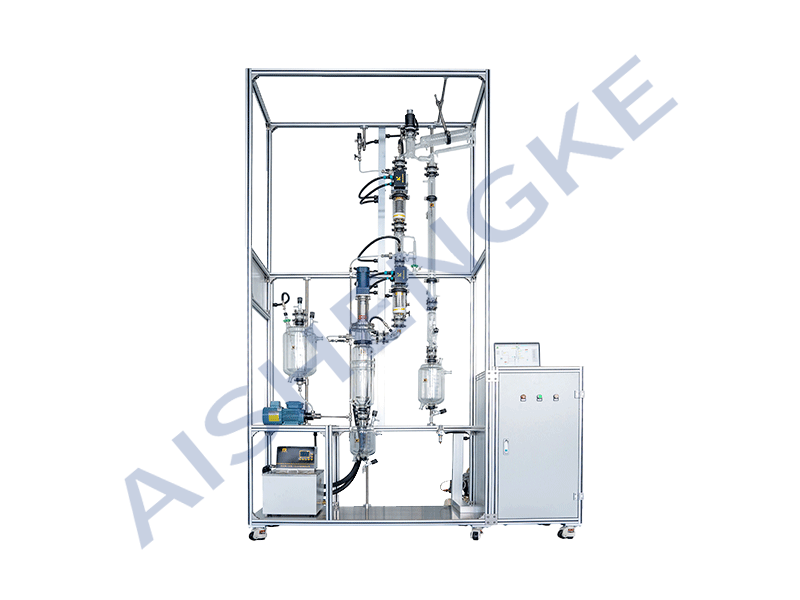

Vacuum Hybrid Fractional Distillation Apparatus

Customized Hybrid Wiped Film Fractionating Column Equipment expertly combine the multi-plate efficiency of fractional columns with the gentle reboiling effect of Wiped-Film Evaporators.

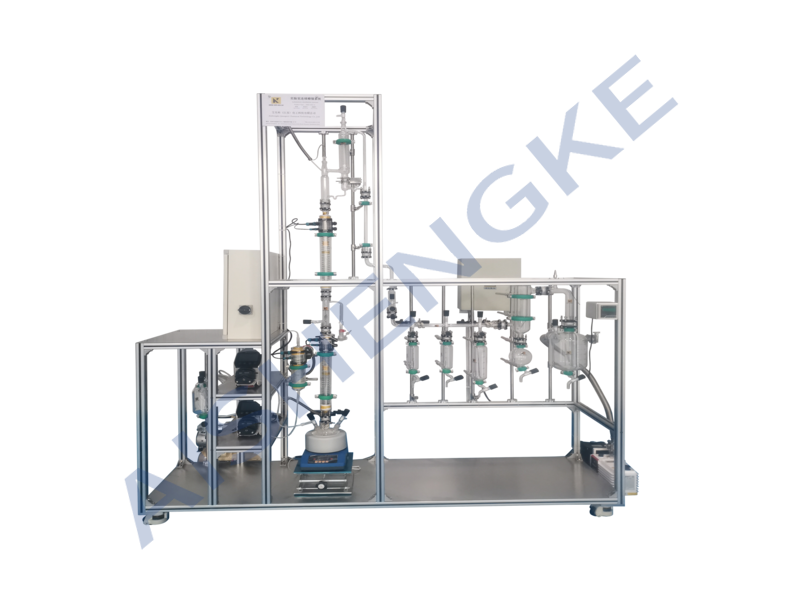

Laboratory Continuous Fractional Distillation Equipment

At ASK Chemical, we offer various types of fractional distillation systems, designed to meet the demands of separating complex mixtures. Our Fractional Distillation Columns are especially suited for critical applications across a diverse range of industries, including fine chemicals, pharmaceuticals, foods, flavors, cosmetics, and extracts. These systems are ideal for situations where a high degree of purity is essential or when the components’ boiling points are closely matched.

Our fractional distillation equipment is available in various sizes, from lab-scale solvent recovery to larger processing scales. choose ASK chemical for fractional distillation systems that deliver exceptional performance and reliability.

Atmospheric And Vacuum Extractive Distillation Unit

Customized Hybrid Wiped Film Fractionating Column Equipment expertly combine the multi-plate efficiency of fractional columns with the gentle reboiling effect of Wiped-Film Evaporators.

Global recruitment of distributors

If you recognize the brand, technology, products and market prospects of Aishengke, we look forward to establishing a strategic partnership with you for win-win cooperation and development. Looking forward to your joining!

Contact Us

Manager Han: +86 198 5022 2118

Landline: +86 0519-85611172

Fax: +86 0519-85611132

Address: No. 109 Liuyanghe Road, Xinbei District, Changzhou City

language

English

العربية

বাংলাদেশ

Български

Hrvatski

Česky

Dansk

Nederland

Esperanto

Slovenski

filipino

Suomi

Français

Maori

Georgian

Deutsch

Ελλάδα

ישראל

इंडिया

Magyarország

Ísland

Indonesia

Irlanda

Italia

日本語

Sovensko

Հայաստան

한국

Kyrgyz

ປະເທດລາວ

Latvian

Lithuanian

Luxembourgish

Macedonian

Малайская

Maltese

Монгол улс

ဗမာ

नेपाल

Norge

ایران

Polska

Portugal

România

Российская

Србија

Србија

Bosanski

Slovenian

Беларус

España

Sverige

Точик

ประเทศไทย

Türk

Azərbaycan

Uzbek

Việt Nam