Laboratory Small Glass Scraped Film Evaporator

Stainless Steel Laboratory Continuous Wiped Film Evaporation Equipment

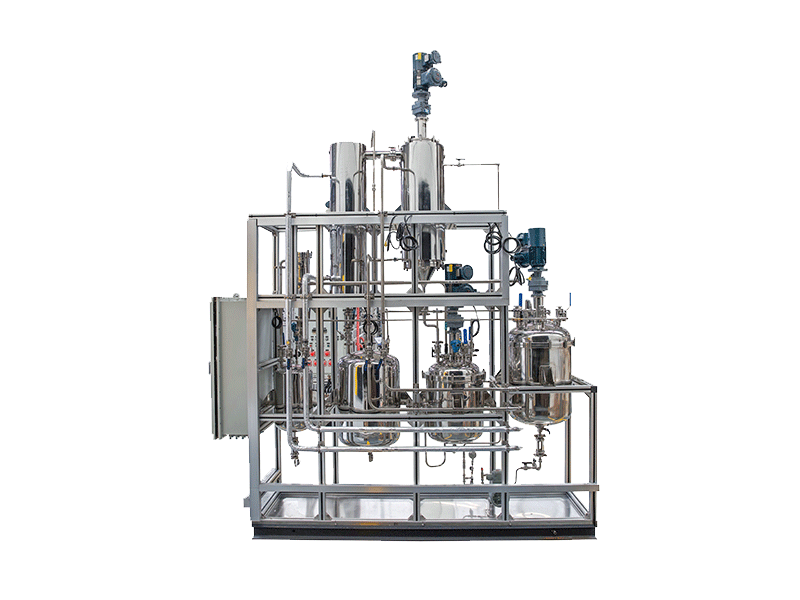

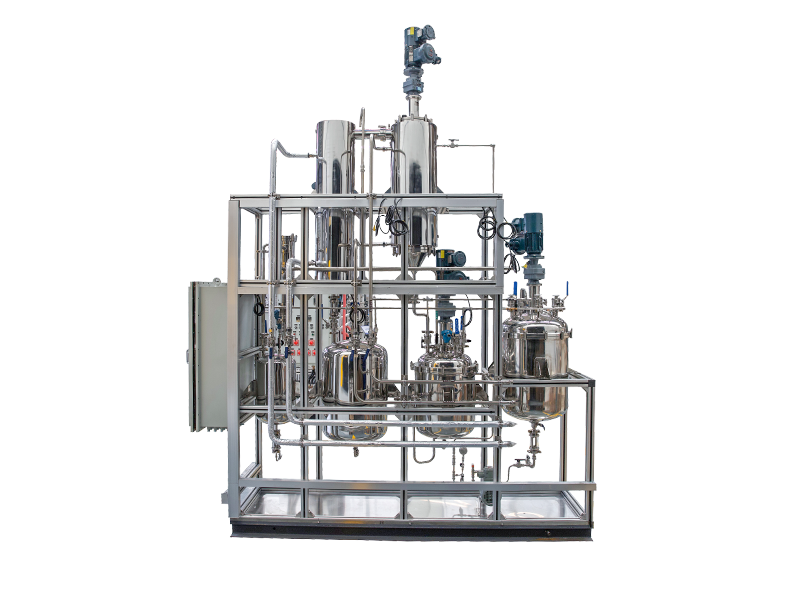

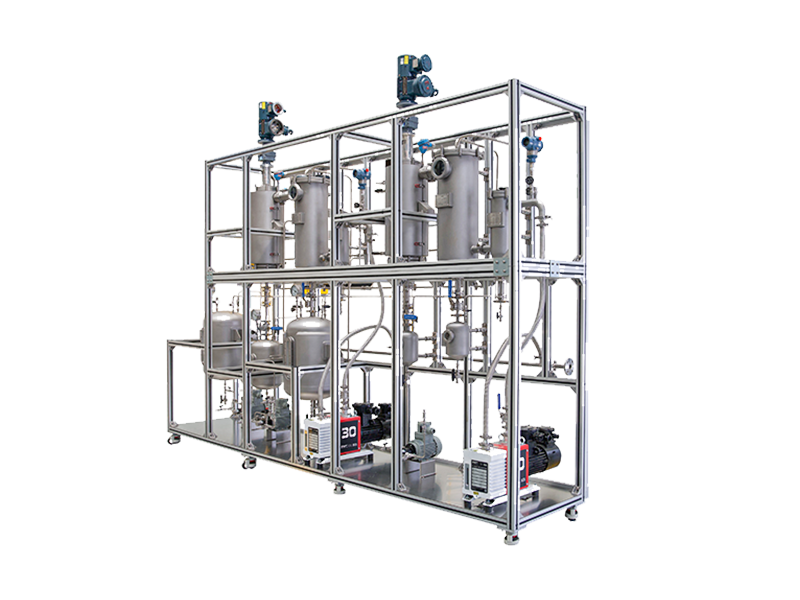

Pilot-scale And Industrial Wiped Film Evaporation Equipment

Level 1 Pilot Scale Stainless Steel Thin Film Evaporation Device

Lab Pilot Scraper Evaporation System

Glass Laboratory Continuous Wiped Film Evaporation Equipment

Laboratory pilot-scale wiped film evaporation equipment

Level 2 Stainless Steel Continuous Wiped Film Evaporation Equipment

Global recruitment of distributors

If you recognize the brand, technology, products and market prospects of Aishengke, we look forward to establishing a strategic partnership with you for win-win cooperation and development. Looking forward to your joining!