How much do you know about the reactor?

Release Time:

2022-10-25

Pageviews:

In the chemical and pharmaceutical fields, the reactor is a comprehensive reaction vessel, and the reactor's structure, function, and configuration accessories are designed according to the reaction conditions. We can complete the pre-set reaction steps with a high degree of automation from the beginning of the feed-reaction-discharge process and the temperature, pressure, mechanical control (stirring, blasting, etc.), reactants/products in the reaction process. Important parameters such as concentration are strictly regulated.

What is a reactor?

In essence, the reactor is a container, a closed container with stirring function, used to complete physical or chemical reactions through various structural designs and supporting equipment to achieve heating, cooling, extraction, evaporation, fractionation, stirring, and mixing functions, so it is widely used in many fields.

What are the different types of reactors?

There are many types of reaction kettles because it has many different classification methods. Common types of reaction kettles are as follows:

1. According to the heating/cooling method, it can be divided into hot water heating, electric heating, heat transfer oil circulating heating, far infrared heating, outer (inner) coil heating, etc., jacket cooling, and inner coil cooling in the kettle, etc.

2. According to the internal pressure of the reactor, it can be divided into positive pressure reactor, negative pressure reactor, and normal pressure reactor.

3. The stirring form of the reaction kettle can be divided into frame type, dispersing disc type, spiral belt type, paddle type, anchor paddle type, turbine type, combined type, etc.

4. According to the heat transfer structure of the reactor, it can be divided into jacket type, inner coil type, outer half tube type and combined type.

5. According to the material of the kettle body, it can be divided into stainless steel reactor, carbon steel reactor, glass reactor, steel lined reactor, and other alloy reactors.

What is the scope of application of the reactor according to the material?

The classification of reaction kettles is based on different types, and the uses of different reaction kettles are also different.

1. Stainless steel reactor

It has many applications, especially for dense and granular materials, and can achieve high-quality stirring effects. There are various stirring methods.

2. Carbon Steel Reactor

Scope of application: environments without corrosive liquids, such as some oil processing.

3. Glass-lined reactor

Glass-lined reactors are divided into single-layer reactors, double-layer reactors, and three-layer reactors, which are suitable for fine chemicals, biopharmaceuticals, new material synthesis, scientific research and other industries.

4. Steel-lined PE reactor

Scope of application: suitable for acids, alkalis, salts and most alcohols. It is suitable for the extraction of liquid food and medicines. It is an ideal replacement for glass fiber reinforced plastic, rubber-lined, stainless steel, enamel, titanium steel, and plastic welded plates.

5. Steel-lined ETFE reactor

Scope of application: The anti-corrosion performance is very good, and it can resist various concentrations of strong oxidants, acids, alkalis, salts, organic compounds and all other strong corrosive chemical media.

What are the components of the reactor?

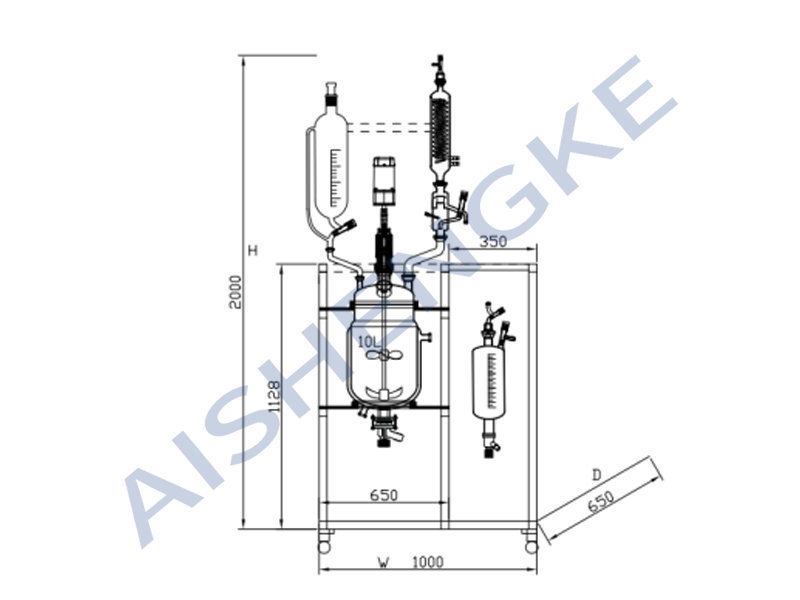

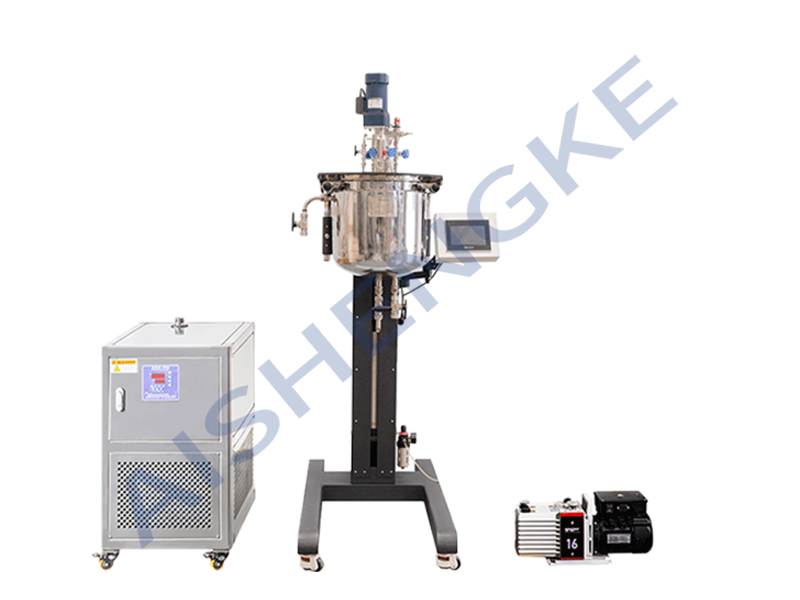

The reactor kettle is mainly composed of a kettle body, a kettle cover, a jacket, a stirrer, a transmission device, and a shaft sealing device.

What are the uses of the reactor?

The main purpose of the reaction kettle is to complete the container for chemical reaction. It can be suitable for various reaction conditions and can be used for chemical reaction of various materials under high temperature and high pressure.

What are the applications of the reactor?

The reactor is mainly used in the fields of biomedicine, fine chemicals, semiconductor materials, new energy materials, etc. The reaction kettle is also the basic equipment of the raw material pharmaceutical factory. The mutual reaction between several raw materials can provide the environment, temperature, pressure, etc. required for the reaction.

What are the differences between glass reactors and stainless steel reactors?

The glass reactor is acid and alkali resistance and corrosion resistance and has good chemical stability, but the ability of heat conduction is poor. The stainless steel reaction kettle is just the opposite. It has excellent thermal conductivity, can be heated quickly, is resistant to high temperature, and is hygienic. It can achieve high stirring effects for both dense and granular materials. However, it has poor resistance to strong acids and alkalis.

How can AISHENGKE help you?

AISHENGKE (Jiangsu) Chemical Technology Co., Ltd. (AI SHENG KE for short) is a company that provides R&D, pilot tests, and industrialized EPC engineering services for scientific research units, university laboratories, factories, and enterprises. Provide customers with small-scale process package development → pilot-scale EPC projects → industrial scale-up design, and project construction. This cooperation method can provide customers with efficient and professional all-around service support and ensure the success rate of project scale-up.

Contact our process design team.

Latest News

2024-09-03

Abstract: Oil deacidification is an important step in food processing, which aims to remove free fatty acids in oil and improve its quality and stability. Traditional deacidification methods have some limitations, such as low efficiency, high energy consumption, and loss of nutrients. In recent years, molecular distillation technology has gradually attracted attention as a new deacidification method. This article will introduce the application of molecular distillation in oil deacidification, including the principle, operation process and advantages, and focus on the outstanding advantages of Aishengke in molecular distillation technology.

Vitamins are products that are closely related to people's lives, and have become one of the main bulk products in the international pharmaceutical and health care products market. The amount of vitamin E is the largest, followed by vitamin A, vitamin C, vitamin D and so on. With the growth of economy and the improvement of people's living standards, the demand for vitamin products will further increase, and people's requirements for their quality and grade will also further increase. Therefore, as an important separation technology in the production of many vitamins, molecular Distillation technology will also play an increasingly important role in the vitamin industry.

Glyceryl monostearate (GMS), abbreviated as monoglyceride, is produced from natural vegetable oils and fats. The active ingredient is purified by molecular distillation technology to more than 90%, also known as molecular distillation monoglyceride. It is the most widely used food Additives, safe to use in the production and processing of food, medicine, plastics, etc., account for more than half of the emulsifier consumption in the market.

The principle of molecular distillation is to make use of the different degrees of affinity between different molecules. By controlling the conditions such as temperature and pressure, the mixture begins to vaporize. Different components in the vapor form liquids in the condenser and are separated according to their boiling points. This distillation method not only has a good separation effect, but also can be repeatedly separated and purified, and is widely used in chemical, pharmaceutical and other fields.

Molecular distillation is a common chemical method used to separate and purify compounds. In the pharmaceutical industry, molecular distillation is widely used in pharmaceutical purification. This article will focus on the application of molecular distillation in pharmaceutical purification and provide some specific examples.

Laboratory vacuum distillation equipment has undergone significant advancements in recent years, driven by the need for higher efficiency, improved safety, and enhanced user experience.

Global recruitment of distributors

If you recognize the brand, technology, products and market prospects of Aishengke, we look forward to establishing a strategic partnership with you for win-win cooperation and development. Looking forward to your joining!