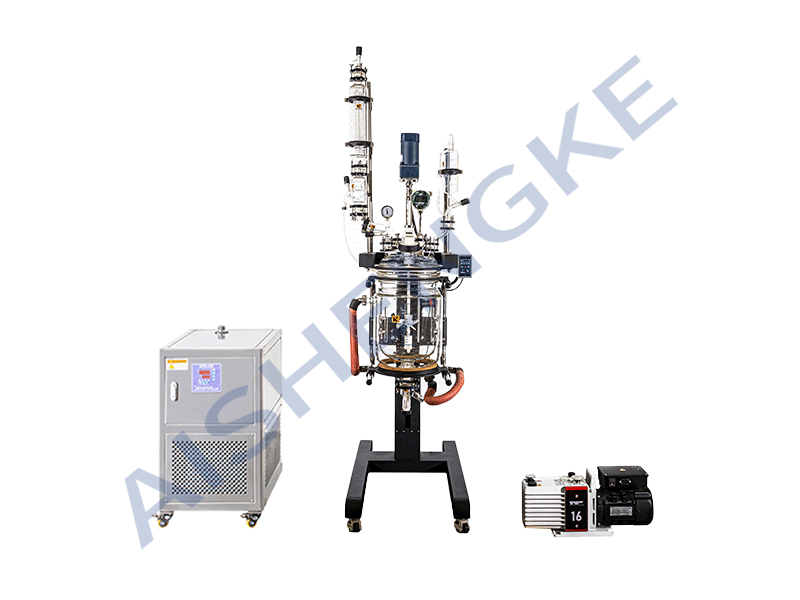

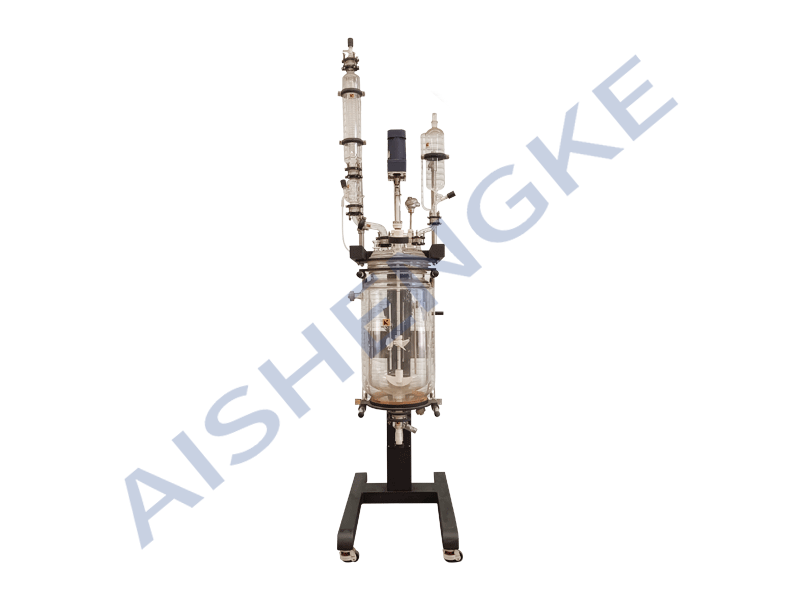

Laboratory Upgrade Pilot 200l Jacketed Glass Reactor

Product Description

Share

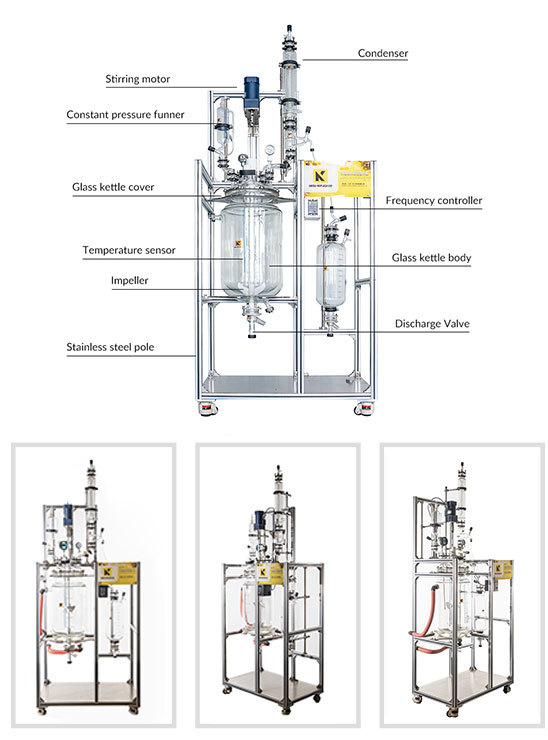

Laboratory Upgrade Pilot 200l Jacketed Glass Reactor

product description

The double-layer glass reactor is designed with double-layer glass. The inner layer can be stirred and reacted by putting the reaction solvent. The interlayer can be connected to different cold and heat sources (refrigerated liquid, hot water or hot oil) for high temperature reaction (with corresponding circulating oil) Bath pot, the temperature can reach 300°C) or low-temperature reaction (with the corresponding low-temperature refrigerant circulation system, the temperature can reach -80°C), or an integrated heating and refrigeration cycle machine; under the set constant temperature, in a closed In the glass reactor, the stirring reaction can be carried out under normal pressure or negative pressure according to the requirements of use, and the reflux and distillation of the reaction solution can be performed. It is an ideal pilot and production equipment for modern fine chemicals, biopharmaceuticals and new material synthesis. Its design makes the experiment safer and more convenient.

Features

1. Variable frequency speed regulation, geared motor, constant speed, no brushes, no sparks, safe and stable, and can work continuously.

2. The whole set of glass is produced with high borosilicate glass GG17 3.3, which has good chemical and physical properties.

3. The overall stainless steel column mobile frame structure, six reaction kettle cover. The large mouth design is easy to clean, and the standard mouth socket can choose to assemble distillation synthesis devices such as reflux, liquid addition, and temperature measurement.

4. Stainless steel wrapped PTFE stirring paddle, suitable for stirring and mixing low to high viscosity liquids.

5. Flange mouth of the lower discharge port and PTFE valve, there is no dead angle in the container, and the detachable lower discharge is convenient for the solid material to be discharged completely and quickly.

6. Alloy steel mechanical seal, PTFE connection port, keep high-precision seal under working condition.

7. Pt100 sensor probe, high temperature measurement accuracy and small error.

We can customize glass reactor if you have any drawings or sketches

OEM and ODM orders are welcome

Welcome to visit our factory!

Product Appearance Display

Application Area

We will help customers to solve out problem in each research, most commonly in petrochemical industry, fine chemical industry, biopharmaceuticals, energy and environmental protection industry.

|

Chemical Engineering |

Scientific Research |

Medical Science |

|

Semiconductor |

Pharmaceuticals |

New Energy |

Key words:

Order Process

Interesting

lnquiry

Inform usage scenarios and technical requirements

Recommended solution

Confirm the details, modify the plan

Customer confirm

Finished product testing, lssue running video and test report

Customer confirm

Production

Pay proofing fee

Recommended solution

Make Sample PI

Packing and shipping

Customer receipt

Guided installation and operation

Satisfied to Sign

Confirm bulk order

Products Can Be Custmized

The volume of the reactor has a wide selection range and can be customized according to customer needs;

The material of the equipment can be customized according to customer requirements, and can provide 304, 316, 316L, titanium alloy, Hastelloy, fluorine lining and other materials for selection.

Company Profile

Aishengke (Jiangsu) Chemical Technology Co., Ltd. was established in 2015. It is an engineering company specializing in providing small-scale research and development, pilot-scale scale-up, electronic-grade materials and fine chemicals industrialization equipment for reaction and separation operations. The company's address is located at No. 109, Liuyanghe Road, Xinbei District, Changzhou, Jiangsu Province. It has an office building of 1500 square meters, a R&D and analysis laboratory of 500 square meters, and an equipment processing and manufacturing plant of 4500 square meters.The company has a senior design team and a processing and manufacturing team, including process development, equipment design, 3D modeling and other designers, glass and stainless steel equipment processing and manufacturing groups, to ensure the high level of process technology development, simulation calculation, mechanical design and manufacturing process.

Why Choose Us

QUALITY

Quality frst is our basic philosophy.

TRANSPORT

Keep strong transportation capacity and excellent price.

WARRANTY

Warranty, parts and labor services.

PROJECT TEAM

A complete project team to provide customers with one-stop service.

Our Certificate

After-sales Service

Replace damaged parts

One year warranty lifetime maintenance

Online technical support

Process

Shot the acceptance video

Submit video within 7 days with broken or missing parts

Reissue parts by express

Faq

Yes, we can provide samples. Considering the high value of our products, samples are not free, but we will give you the best price.

We Have Our Own Factory. We Are Experts In Reaction And Separation Process Technology. With Wanhua, Huawei, Smic And Many Other Customers, It Has Won Wide Acclaim In The Industry.

rotary evaporator, alcohol recovery equipment, short path distillation kit, glass molecular distillation equipment, falling film evaporator, jacketed glass reactor and other lab equipment.

Generally it is within 7 working days after receiving the payment if the goods are in stock. Or it is 15 working days if the goods are not in stock, depending on order quantity.

Payment≤15,000USD, 100% in advance. Payment≥15,000USD, 70% T/T in advance, balance before shipment. (If you are concerned about payment security for the first order, we advise you can place Trade Assurance Order via Alibaba. you will get 100% payment refund if we can't meet agreed delivery time.)

Online Message

Online Message

Recommended product

Lifting Double Jacketed 10L Glass Reactor

Lab 316l High Pressure Jacketed Stainless Steel Chemical Reactor Vessel

1L 2L 3L 5L Laboratory Small Double Jacketed Glass Stirred Reactor

50l 100l Lab Pilot-scale Chemical Double Jacketed Glass Reactor Vessel(lifting type)

Global recruitment of distributors

If you recognize the brand, technology, products and market prospects of Aishengke, we look forward to establishing a strategic partnership with you for win-win cooperation and development. Looking forward to your joining!