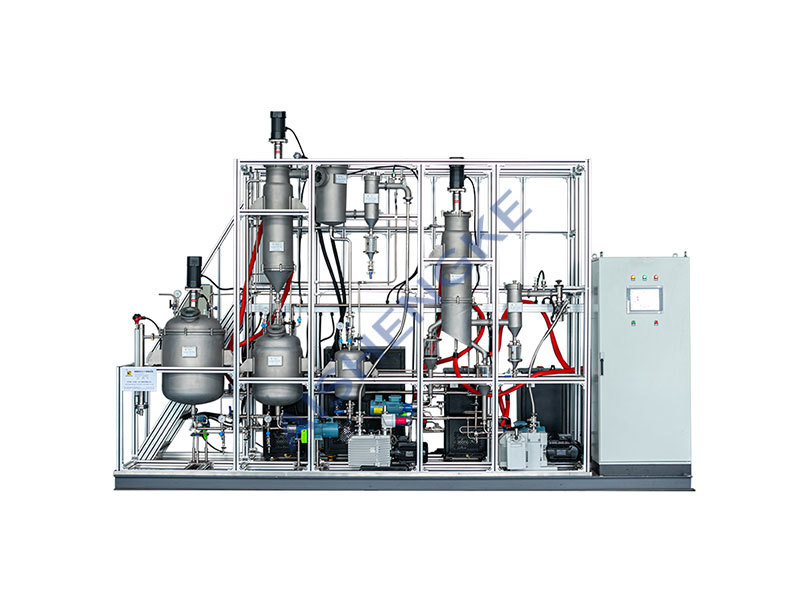

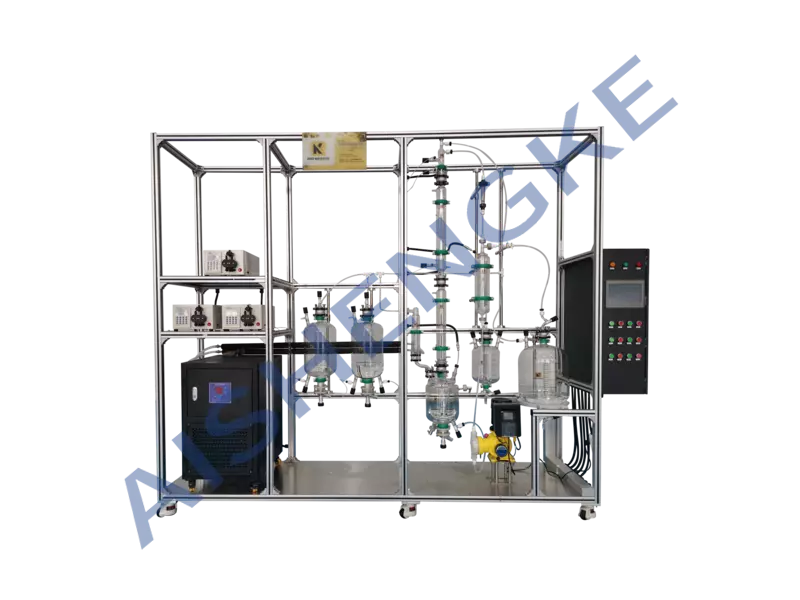

Stainless Steel 304 316L Vacuum Wiped Film Molecular Distillation System

Pilot-scale And Industrial Wiped Film Evaporation Equipment

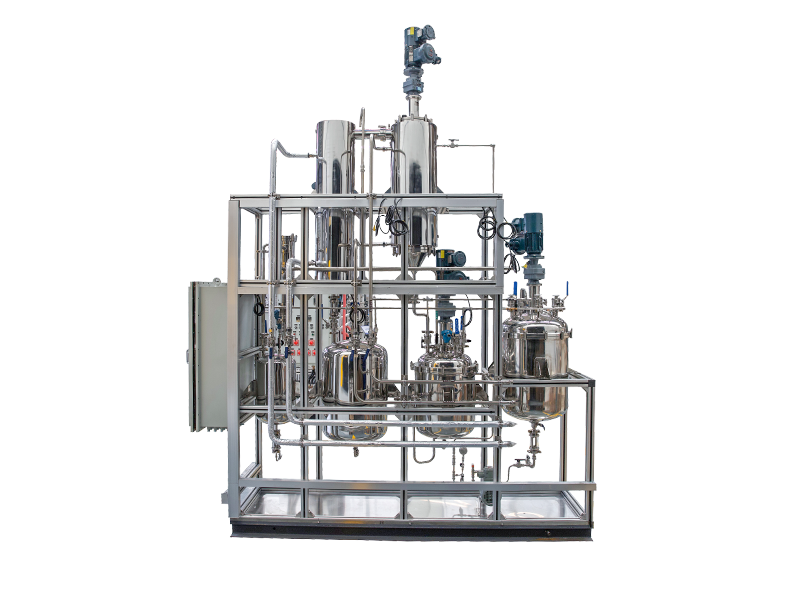

Laboratory Upgrade Pilot 200l Jacketed Glass Reactor

Level 1 Pilot Scale Stainless Steel Thin Film Evaporation Device

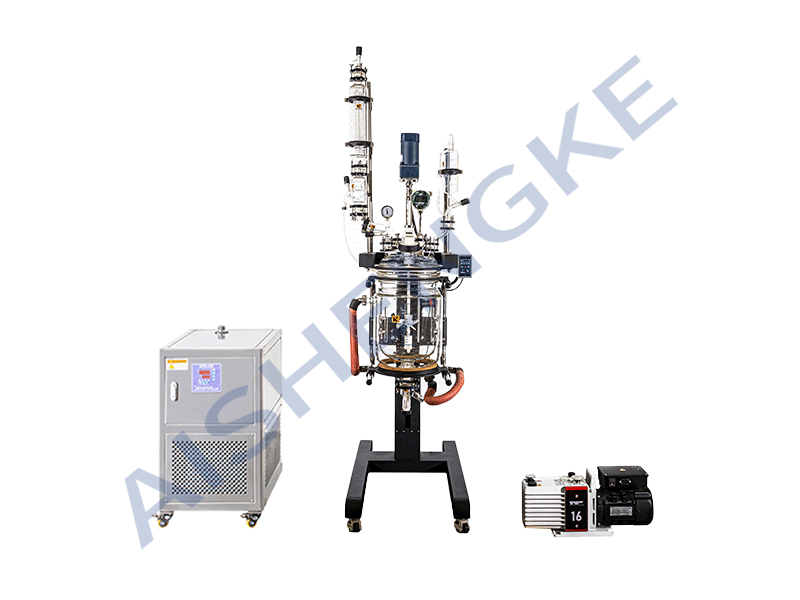

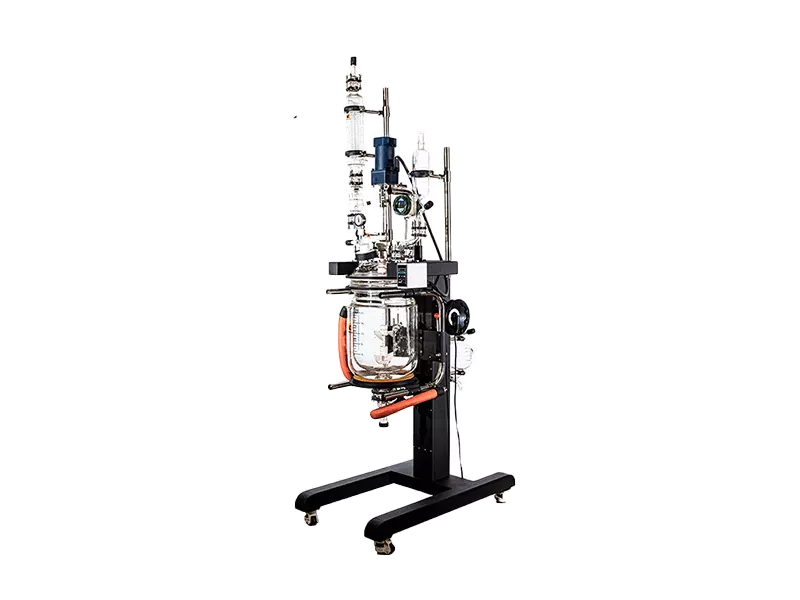

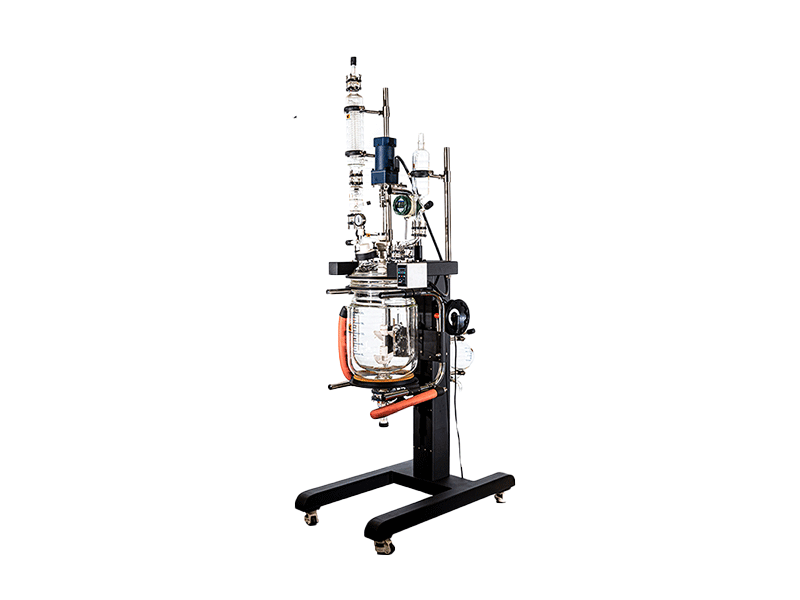

10L 20L 50L 100L 150L Explosion-proof Double Jacketed Glass Reactor

Liftable 5l Lab Stainless Steel Reactor Vessel

Liftable 20l Jacketed Stainless Steel Reactor

Liftable 30l Stainless Steel Autoclave Reactor

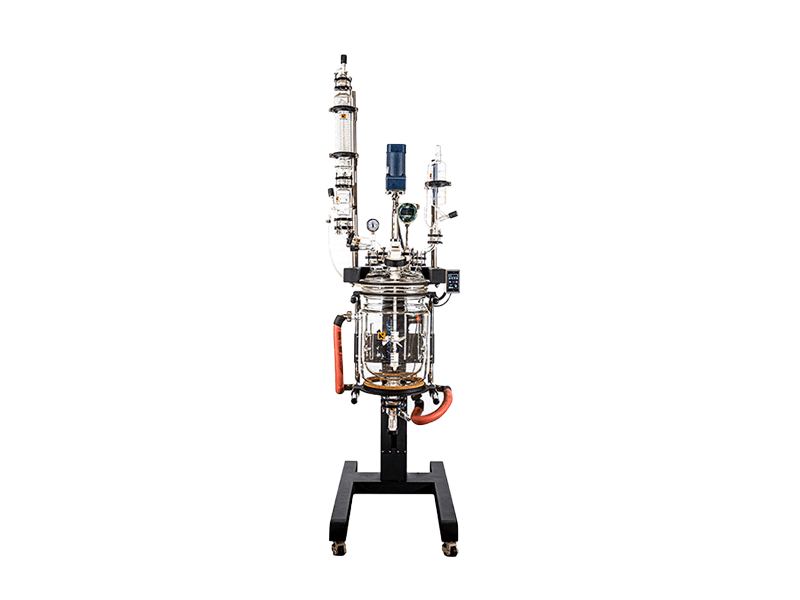

Lifting Double Jacketed 10L Glass Reactor

Lab Pilot Scraper Evaporation System

Lifting Double Jacketed 20L Glass Reactor

Glass Laboratory Continuous Wiped Film Evaporation Equipment

Lifting Double Jacketed 30L Glass Reactor

Liftable 50l High Pressure Stainless Steel Reactor

Lifting Double Jacketed 50L Glass Reactor

Lifting Double Jacketed 100L Glass Reactor

Lab 316l High Pressure Jacketed Stainless Steel Chemical Reactor Vessel

50L 100L 150L Explosion-proof Double Jacketed Chemical Chemical Glass Reactor

Provide Customizable Chemglass Jacketed Reactor & Glass Chemical Reactor

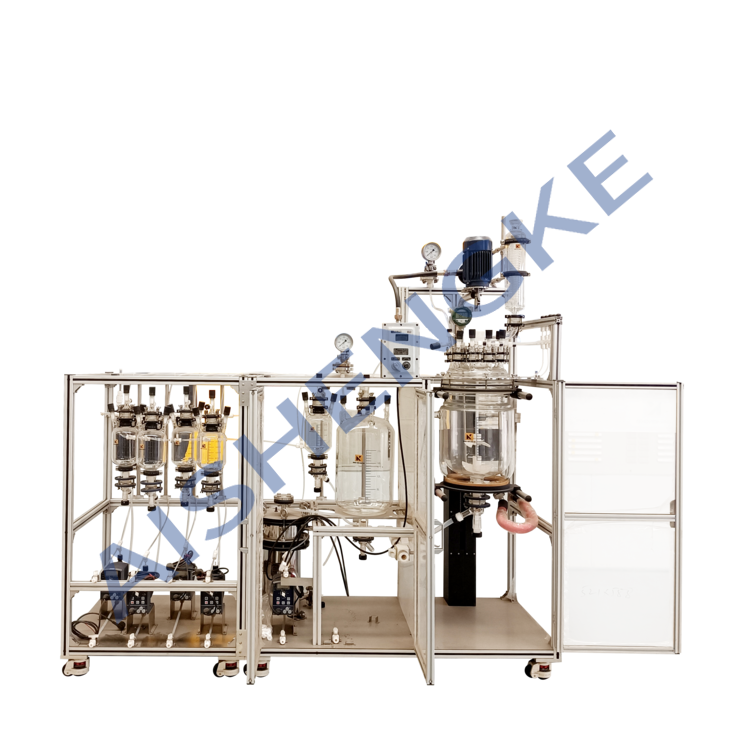

Multi-tank series reaction unit & Continuous tank reactor

Glass Continuous Purification Reactor

Fixed bed catalytic reaction and hydrogenation unit

25ml Laboratory Small Stainless Steel Autoclave Hydrothermal Synthesis Reactor

100ml Laboratory Small Stainless Steel Autoclave Hydrothermal Synthesis Reactor

Global recruitment of distributors

If you recognize the brand, technology, products and market prospects of Aishengke, we look forward to establishing a strategic partnership with you for win-win cooperation and development. Looking forward to your joining!